Manufacturing Case Study: Enhancing Production Visibility with Industrial Android All-in-One Panels

![]() 2025-12-12

2025-12-12

![]() Hopestar

Hopestar

For many manufacturers, real-time production visibility remains a major challenge. Even as digital transformation gains momentum, many shop floors still rely on manual reporting, scattered data, and delayed communication. This results in slow response times, limited equipment transparency, and inconsistent production records.

A precision parts manufacturer recently encountered similar issues when expanding its operations. Although the company invested in new CNC machines and automated tools, the lack of a unified data interface meant that supervisors still needed to walk across the workshop to collect updates, check machine status, and verify work orders. To achieve better control and higher efficiency, the company sought a practical, scalable solution that could digitize the entire shop-floor workflow.

After evaluating several options, they deployed a series of 10.1-inch industrial Android HMI all-in-one panels and connected them directly to their MES (Manufacturing Execution System). This allowed real-time communication between equipment, operators, and management, transforming manual workflows into a streamlined digital process.

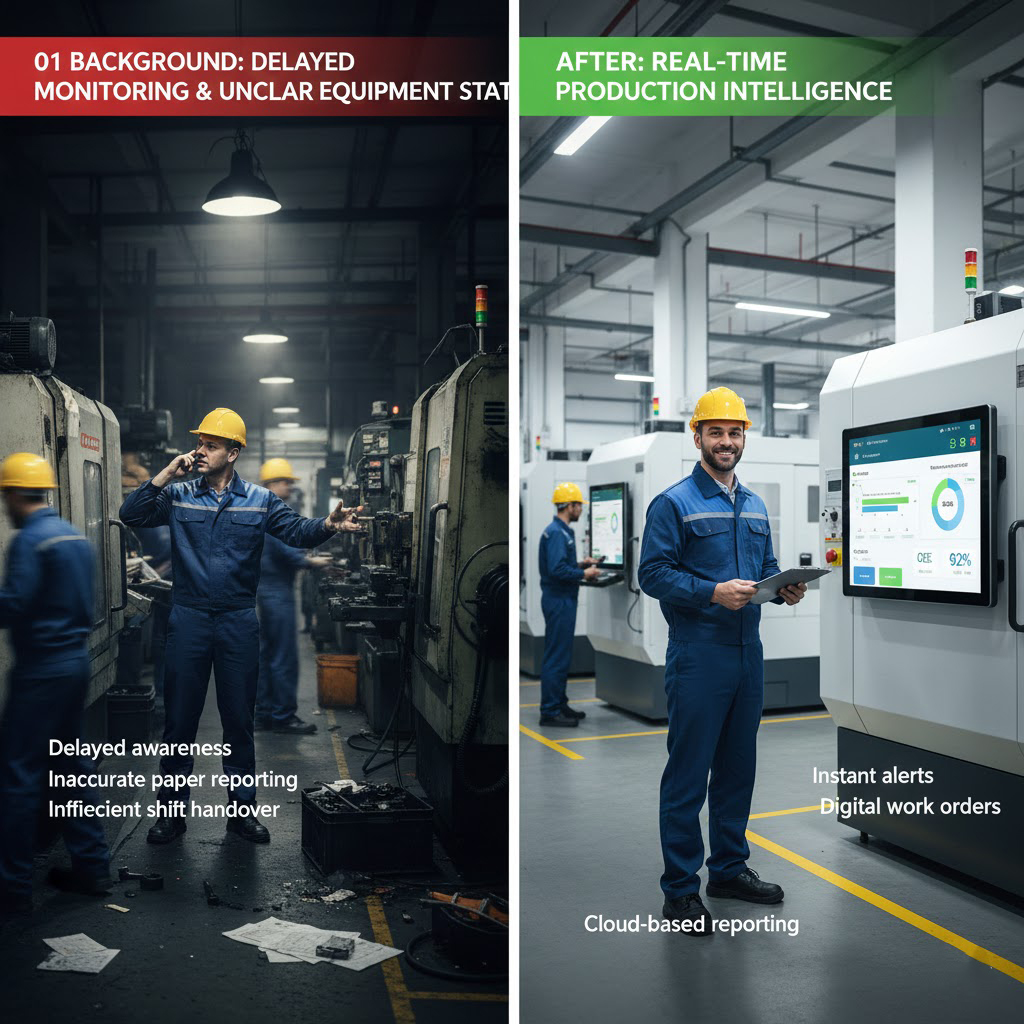

01 Background: Manual Monitoring and Limited Transparency

The challenges the company faced were typical for growing manufacturing facilities:

Status information was not updated in real time.

Machine downtime or quality issues were often discovered only during routine inspections, delaying corrective action.

Paper-based records caused inconsistencies.

Operators filled out production sheets by hand, making data prone to errors or incomplete entries.

Communication between shifts was inefficient.

Without a unified digital system, important details were sometimes overlooked during handovers.

Management lacked comprehensive visibility.

Supervisors could not easily track output, utilization rates, or machine performance trends.

These issues affected production planning, equipment utilization, and—most critically—response time when abnormalities occurred. The management team recognized that improving visibility was essential for stable and scalable operations.

02 Solution: Deploying 10.1-Inch Android HMI Panels Connected to the MES

To address the challenges, the company installed 10.1-inch industrial Android all-in-one panels at key stations throughout the shop floor. Built for industrial conditions, the devices offer stable performance, intuitive touch operation, and strong compatibility with existing MES applications.

Key components of the solution included:

MES-linked real-time status display

Machines continuously transmit operational data to the MES, and the panels present this information directly to operators—showing running status, progress, alarms, and output counts.

Digital work orders and instructions

Each operator receives updated tasks and process steps on the screen. This eliminates paper documents and ensures every workstation follows the latest version.

Instant abnormal reporting

Any unexpected machine stop or parameter deviation triggers a real-time alert, which is sent simultaneously to operators, supervisors, and the MES dashboard.

On-screen data input and confirmation

Operators record production results directly on the panel, reducing manual paperwork and improving data integrity.

Remote monitoring for managers

Supervisors can view detailed production dashboards from an office or separate facility, enabling efficient multi-line management.

Thanks to their compact size and flexible installation options, the 10.1-inch panels were easily mounted on machine frames, workbenches, and wall brackets, requiring minimal modification to the existing production layout.

03 Results: Improved Responsiveness, Smoother Collaboration, and Data Transparency

Within months of deployment, the factory reported noticeable improvements in efficiency, productivity, and operational clarity. The impact was reflected in several key areas:

● Enhanced real-time visibility

Operators gained immediate insight into equipment status and work progress, while management accessed accurate production metrics without physically visiting each workstation. This significantly reduced information delays and improved decision-making speed.

● Faster response to abnormal events

Automatic alerts ensured that issues such as tool wear, overheating, or material shortages were addressed quickly. The average response time decreased, and the factory experienced fewer extended downtime events.

● Higher accuracy through digital documentation

Replacing paper forms with digital entries reduced human error. Work orders were clearer, shift transitions more organized, and historical data more reliable for auditing and quality analysis.

● Stronger coordination between teams

Remote monitoring capabilities enabled supervisors and engineers to support multiple lines without constant on-site presence. This improved communication, reduced unnecessary travel inside the workshop, and optimized resource allocation.

By integrating industrial Android all-in-one panels with their MES, the manufacturer achieved a more transparent, data-driven production environment. The system helped the team replace manual processes with real-time digital workflows, improving equipment utilization, collaboration efficiency, and overall production stability.

This case highlights how even small, targeted digital upgrades—such as deploying compact HMI panels—can deliver significant value in modern manufacturing environments. It also lays the groundwork for future initiatives, including predictive maintenance, automated reporting, and multi-site production management.

86 13392660243

86 13392660243 hope17@cnhopestar.com

hope17@cnhopestar.com

whatsapp

whatsapp

Smart Retail Case Study: Uhopestar Android POS Tablets Streamline Checkout for a Growing Supermarket Chain

Smart Retail Case Study: Uhopestar Android POS Tablets Streamline Checkout for a Growing Supermarket Chain